【MM MRP】PA-SCM525 Unit2 Lot-Size$Rounding Profile(MRP_2)

1.Lot size calculation

Three groups of procedures exist for calculating the lot size:

- Static lot-sizing procedures

- Period lot-sizing procedures

- Optimizing lot-sizing procedures

The result of the lot-sizing calculation is the amount of a material for production or acquisition.

Define lot-sizing procedures in Customizing for Materials Management under

Consumption-Based Planning → Planning → Lot-Size Calculation → Define Lot-Sizing Procedure.

1.1 Static lot size calculation

- lot-for-lot order quanlity

- fixed order quanlity

- replenish to maxmium stock level

In the static lot size procedure,the procument quantity is calculated using only the enterted quantities in the material master data.

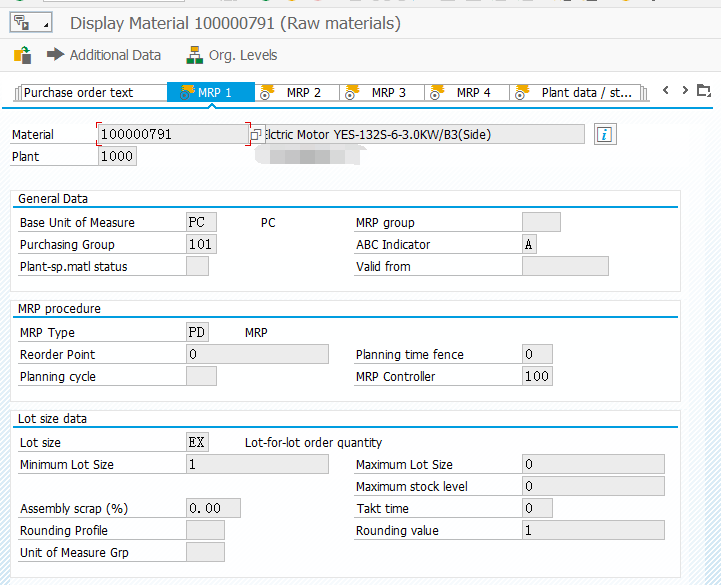

2.Rounding Profile

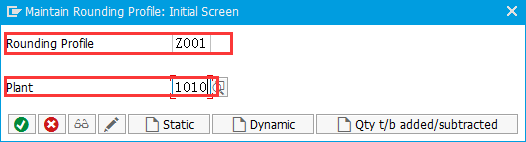

2. Miantain Rounding Profile

Path:IMG-->Materials management-->Consumption-based planning-->Planning-->Lot-size Calculation-->Maintain Rounding Profile

You can define the rounding profiles in conjunction with a plant,also can leave it empty.For the purpose of this exercise,you should leave the plant field empty.Choose Static:

Save.

Some concept questions:

1. What options are there in the SAP system for executing a planning run?

Answer:

Single-item planning (single-level or multi-level)

Total planning online

Total planning in background processing

2. Name the individual subprocesses of a planning run.

Answer:

1. Check the planning file

2. Net requirements calculation

3. Lot-size calculation

4. Scheduling

5. Type of procurement proposals

With the corresponding settings, the system determines a source of supply

during a planning run for externally procured materials, and assigns them

directly to the procurement proposal.

3. The low-level code is the lowest level in which a material appears in all

BOMs.

Answer: True

The low-level code is the lowest level in which a material appears within

all BOMs. The code determines the sequence in which the materials are

planned: First, the system plans all materials with level 0, then all with

level 1, and so on. The lower the low-level code is, the higher the number

assigned to the level.

4. Name the possible planning process types in a total planning run.

Answer: The following planning process types are available in total

planning:

NEUPL for regenerative planning

NETCH for net change planning in the total horizon

NETPL for net change planning only within the planning horizon.

2009 © 2009 SAP AG. All rights reserved. 125

Test Your Knowledge SCM525

5. The plant parameters have higher priority than the MRP groups.

Answer: False

If a setting is possible on several levels, the setting in the MRP group that is

assigned to the material has priority over the setting in the plant parameters.

In total planning, the system checks for each material whether the material

was allocated a MRP group. If no MRP group is allocated for the material,

the material is planned using plant parameters. If a MRP group is allocated

to the material, the material is planned using MRP group parameters.

6. In which screen areas can you break down a MRP list?

Answer: A, C, D

Each MRP list is divided into a header section and an item section. In the

MRP list header, material data is recorded, for example, the material number,

the plant, and MRP parameters. The item section contains information on the

individual MRP elements (purchase requisitions, planned orders, purchase

orders, and so on). In the left-hand tree in the MRP list, there is a material

tree that you can choose to either show or hide.

7. What are the options for converting a planned order into a purchase

requisition?

Answer:

Individual conversion

Collective conversion

There is a difference between collective conversion online and collective

conversion in background processing.

126 © 2009 SAP AG. All rights reserved. 2009

SCM525 Test Your Knowledge

8. Changes made after the planning date are not considered in the MRP list.

Answer: True

The system creates MRP lists during the planning run depending on the

creation indicator MRP lists. These lists contain the planning results for the

material. The MRP list always displays the stock/requirements situation at

the time of the last planning run, and provides a work basis for the MRP

controller. Any changes made after the planning date are not considered.

The list is static.

In the current stock/requirements list, the most up-to-date development of

stocks and requirements displays. The main difference between the MRP list

and the stock/requirements list is that each time the stock/requirements list is

called, the system re-reads the various MRP elements and displays the most

up-to-date situation. As a result, you always see the most recent availability

situation for the material in the stock/requirements list. Changes made after

the planning date are displayed directly. The list is dynamic.

9. What settings can you define in Customizing for Consumption-Based

Planning for the exception messages?

Answer: Define the following settings in Customizing for

Consumption-Based Planning for the exception messages:

Whether an exception message should be created

The priority of the exception messages, if several exception messages

were created during the planning run for an MRP element

Which exception messages are to be grouped together into an exception

group

Which exception messages lead to the creation of a MRP list if you

set the creation indicator Create MRP list depending on exception

messages

The exception message text can be changed

10. Which of the following procedures belong to the static lot-sizing procedure?

Answer: A, D, E

The following belong to the static lot-sizing procedure:

Lot-for-lot order quantity

Fixed lot size

Replenish to maximum stock level.

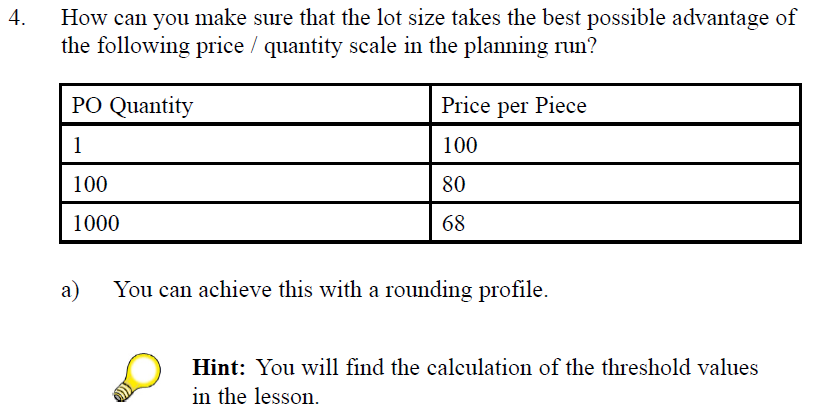

11. Aside from the lot-sizing procedure, name other ways of influencing a lot

size in the material master record.

Answer: Other lot size data in the material master record that influences

the procurement quantity includes:

Rounding value

Rounding profile

Minimum lot size

Maximum lot size

12. Describe the function of a rounding value.

Answer: If you specify a rounding value in the material master record, this

means that the procurement quantity includes the multiple of a purchase

order unit during lot-size calculation. This may be useful if rounding up to

the next pallet size, as pallets are only delivered if they are complete.

浙公网安备 33010602011771号

浙公网安备 33010602011771号