四足机器人MPC+WBC方案

四足机器人MPC+WBC方案

一、MPC:

系统方程:

状态变量:\(x_r = (h_{com}, q_b, q_j) \in R^{24}\), 包含6维质心点动量,6维机身位姿,3*4个关节角度

输入变量:\(u = (f_{c1}, ......, f_{c4}, v_j) \in R^{3*4+12}\), 包含4个腿末端的3维力,12个关节速度

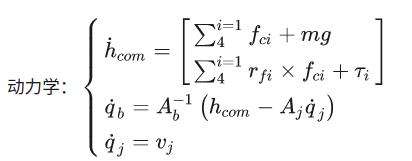

动力学:

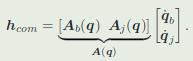

其中\(f_{ci}\)是4足末端的接触力,\(r_{fi}\)是足触地相对于质心的位置矢量, \(h_{com}\)是质心动量,A是质心动力学的刚体惯性矩阵

动量=mv;所以

动量求导后,变成ma,就是力。

cost function:

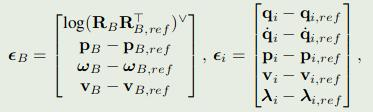

- 机体跟随误差(姿态,位置,角速度,速度)

- 足轨迹跟随误差(关节角,关节角速度,接触脚在世界坐标系下的位置和速度,接触力)

- 关节速度和接触力中的高频内容惩罚

- relaxed barrier functions 不等式约束

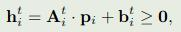

机体误差和足迹轨迹误差:

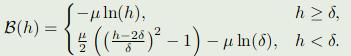

relaxed barrier functions 不等式约束:

-

relaxed barrier functions:

![]()

-

全惩罚项:

![]()

-

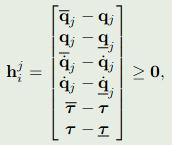

关节角、角速度、关节力矩上下限:

![]()

-

落足区域:

![]()

-

摩擦锥约束:

![]()

-

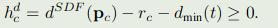

障碍物约束:

![]()

等式约束:

- \(f_{ci} = 0\) 摆动腿的接触力为0

- \(v_{ci} = 0\) 支撑腿的接触速度为0

- \(v_{ci}n_z = v^{*}_z\) 对于摆动相,参考轨迹仅在地表法线方向约束(这样即保证了足部以指定的速度抬离并离地,同时又在切线方向有足够的灵活度)

二、WBC:

坐标系:

I:惯性坐标系,世界坐标系?

B:自由浮动基座,baselink?

C:地面坐标系,x,y方向和B坐标系相同,Z坐标系垂直于地形

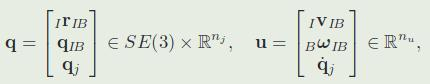

2.1 模型:

\(n_u = 6 + n_j\),6+12=18

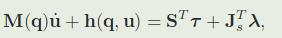

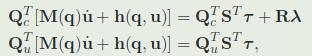

系统方程:

\(M(q) \in R^{n_u * n_u}\):质量矩阵

\(h(q,u) \in R^{n_u}\):科里奥利力、离心力、重力项

如果所有的关节都能驱动,\(n_{\tau} = n_j\),也就是12

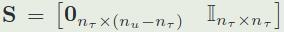

\(J_s \in R^{3n_c * n_u}\):堆叠约束雅可比,\(J_s = [J^T_{C_1} ...... J^T_{C_{nc}}]\)

\(n_c\)是接触点数量,正常是4个

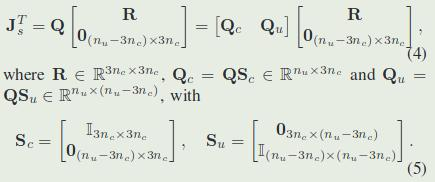

支撑接触点的运动约束:

将脚建模为点接触,\(r_{IC}\)是力,支撑的时候,是静止的,所以速度和加速度为0

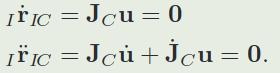

支撑一致性动力学:

如果运动保持在上诉的接触约束的零空间中,动力学方程可以投影到缩减空间动力学,通过QR分解得到支撑雅可比

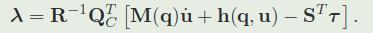

2.2 零空间:

任务定义:

零空间定义:

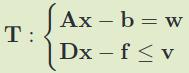

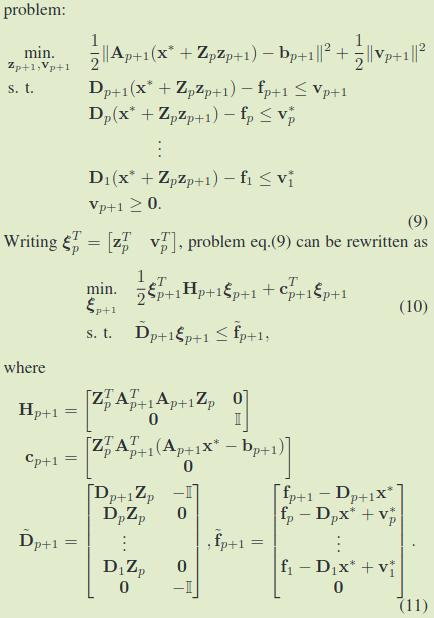

\(Z_p = N(\underline{A}_p)\), \(\underline{A}_p\)是多任务A的集合

\(x = s^{*} + Z_p z_{p+1}\),\(z_{p+1}\)是行空间\(Z_p\)的一个向量

求解一个新的任务\(T_{p+1}\),意味着求解\(z^{*}_{p+1}\)和\(v^{*}_{p+1}\)

\(Z_p\)是任务堆叠矩阵A的零空间,可以用QR或SVD分解得。

任务很多的时候,可以使用迭代求解零空间:

stackedZ_ = stackedZPrev_ * (task_.a_ * stackedZPrev_).fullPivLu().kernel();

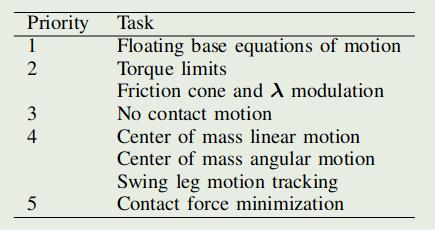

2.3 多任务:

1. 等式任务:

- 浮动基座系统方程:

\([M_{fb} -J^{T}_{s_{fb}} ] \xi_d = -h_{fb}\)

\(M_{fb},J^{T}_{s_{fb}}, h_{fb}\)分别是惯性矩阵的前6行(关于6自由度基座相关),基座的雅可比,非线性项

\(\xi_d = [\dot{u}^{T}_{d}, \lambda^T_d]^T \in R^{n_u+n_c}\),关节加速度和接触力

Task WbcBase::formulateFloatingBaseEomTask() {

auto& data = pinocchioInterfaceMeasured_.getData();

matrix_t s(info_.actuatedDofNum, info_.generalizedCoordinatesNum);

s.block(0, 0, info_.actuatedDofNum, 6).setZero();

s.block(0, 6, info_.actuatedDofNum, info_.actuatedDofNum).setIdentity();

matrix_t a = (matrix_t(info_.generalizedCoordinatesNum, numDecisionVars_) << data.M, -j_.transpose(), -s.transpose()).finished();

vector_t b = -data.nle;

return {a, b, matrix_t(), vector_t()};

}

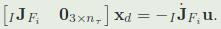

- 运动等式约束:

只要运动在接触零空间内,接触力就可以表示为扭矩和产生运动的线性组合,在运动空间和扭矩空间寻找解:

\(x_d = [\dot{u}^{T}_{d}, \tau^T_d]^T\)

运动等式方程:

\(Q^T_u [-M(q),S^T]x_d = Q^T_u h(q,u)\)

- 接触运动约束:

摆动腿从腾空状态过度到触地状态后,为防止足端继续移动,需要保证足端的速度为零

Task WbcBase::formulateNoContactMotionTask() {

matrix_t a(3 * numContacts_, numDecisionVars_);

vector_t b(a.rows());

a.setZero();

b.setZero();

size_t j = 0;

for (size_t i = 0; i < info_.numThreeDofContacts; i++) {

if (contactFlag_[i]) {

a.block(3 * j, 0, 3, info_.generalizedCoordinatesNum) = j_.block(3 * i, 0, 3, info_.generalizedCoordinatesNum);

b.segment(3 * j, 3) = -dj_.block(3 * i, 0, 3, info_.generalizedCoordinatesNum) * vMeasured_;

j++;

}

}

return {a, b, matrix_t(), vector_t()};

}

- 质心轨迹跟踪:

由MPC得到质心期望位置、速度、加速度,分别为\(p^{des}_{com}, \dot{p}^{des}_{com}, \ddot{p}^{des}_{com}\)

由\(\ddot{p}^{des}_{com} = \ddot{p}_{com} + K_p e_{com} + K_d \dot{e}_{com}\)

得:\([J_{com}, 0_{6*36}] x_d = \ddot{p}_{com} + K_p e_{com} + K_d \dot{e}_{com} - \dot{J}_{com} \dot{q}\)

其中\(e_{com}\)是位置误差,\(\dot{e}_{com}\)是速度误差。

- 足端轨迹跟踪:

足端定义五次Hermite splines曲线,提供期望位置,速度和加速度在坐标系C中。

\([J_{ci}, 0_{3*39}] x_d = \ddot{p}_{ci} + K_p e_{ci} + K_d \dot{e}_{ci} - \dot{J}_{ci} \dot{q}\)

Task WbcBase::formulateSwingLegTask() {

eeKinematics_->setPinocchioInterface(pinocchioInterfaceMeasured_);

std::vector<vector3_t> posMeasured = eeKinematics_->getPosition(vector_t());

std::vector<vector3_t> velMeasured = eeKinematics_->getVelocity(vector_t(), vector_t());

eeKinematics_->setPinocchioInterface(pinocchioInterfaceDesired_);

std::vector<vector3_t> posDesired = eeKinematics_->getPosition(vector_t());

std::vector<vector3_t> velDesired = eeKinematics_->getVelocity(vector_t(), vector_t());

matrix_t a(3 * (info_.numThreeDofContacts - numContacts_), numDecisionVars_);

vector_t b(a.rows());

a.setZero();

b.setZero();

size_t j = 0;

for (size_t i = 0; i < info_.numThreeDofContacts; ++i) {

if (!contactFlag_[i]) {

vector3_t accel = swingKp_ * (posDesired[i] - posMeasured[i]) + swingKd_ * (velDesired[i] - velMeasured[i]);

a.block(3 * j, 0, 3, info_.generalizedCoordinatesNum) = j_.block(3 * i, 0, 3, info_.generalizedCoordinatesNum);

b.segment(3 * j, 3) = accel - dj_.block(3 * i, 0, 3, info_.generalizedCoordinatesNum) * vMeasured_;

j++;

}

}

return {a, b, matrix_t(), vector_t()};

}

2. 不等式任务:

- 力矩限制:

\(\begin{bmatrix} 0_{12*18} & E_{12*12} & 0_{12*12} \\ 0_{12*18} & -E_{12*12} & 0_{12*12} \\ \end{bmatrix} x_d <= \begin{bmatrix} \tau^{max}_{12*1} \\ -\tau ^{min}_{12*1} \\ \end{bmatrix}\)

Task WbcBase::formulateTorqueLimitsTask() {

matrix_t d(2 * info_.actuatedDofNum, numDecisionVars_);

d.setZero();

matrix_t i = matrix_t::Identity(info_.actuatedDofNum, info_.actuatedDofNum);

d.block(0, info_.generalizedCoordinatesNum + 3 * info_.numThreeDofContacts, info_.actuatedDofNum, info_.actuatedDofNum) = i;

d.block(info_.actuatedDofNum, info_.generalizedCoordinatesNum + 3 * info_.numThreeDofContacts, info_.actuatedDofNum,

info_.actuatedDofNum) = -i;

vector_t f(2 * info_.actuatedDofNum);

for (size_t l = 0; l < 2 * info_.actuatedDofNum / 3; ++l) {

f.segment<3>(3 * l) = torqueLimits_;

}

return {matrix_t(), vector_t(), d, f};

}

- 足端作用力限制:

足端z轴方向的作用力需大于零,并且x和y轴方向牵引力要小于摩擦力。其中\(S^1_{12*1}\)和\(S^2_{12*12}\)为选择矩阵,选择触地足端作用力;

\(f^1_{12*1}\)和\(f^2_{12*1}\)表示各方向摩擦力的上限和下限。

\(\begin{bmatrix} 0_{12*18} & 0_{12*12} & S^1_{12*12} \\ 0_{12*18} & 0_{12*12} & -S^2_{12*12} \\ \end{bmatrix} x_d <= \begin{bmatrix} u * f^1_{12*1} \\ -u * f^2_{12*1} \\ \end{bmatrix}\)

Task WbcBase::formulateFrictionConeTask() {

matrix_t a(3 * (info_.numThreeDofContacts - numContacts_), numDecisionVars_);

a.setZero();

size_t j = 0;

for (size_t i = 0; i < info_.numThreeDofContacts; ++i) {

if (!contactFlag_[i]) {

a.block(3 * j++, info_.generalizedCoordinatesNum + 3 * i, 3, 3) = matrix_t::Identity(3, 3);

}

}

vector_t b(a.rows());

b.setZero();

matrix_t frictionPyramic(5, 3); // clang-format off

frictionPyramic << 0, 0, -1,

1, 0, -frictionCoeff_,

-1, 0, -frictionCoeff_,

0, 1, -frictionCoeff_,

0,-1, -frictionCoeff_; // clang-format on

matrix_t d(5 * numContacts_ + 3 * (info_.numThreeDofContacts - numContacts_), numDecisionVars_);

d.setZero();

j = 0;

for (size_t i = 0; i < info_.numThreeDofContacts; ++i) {

if (contactFlag_[i]) {

d.block(5 * j++, info_.generalizedCoordinatesNum + 3 * i, 5, 3) = frictionPyramic;

}

}

vector_t f = Eigen::VectorXd::Zero(d.rows());

return {a, b, d, f};

}

浙公网安备 33010602011771号

浙公网安备 33010602011771号