基于多层编码遗传算法的车间调度系统

问题描述与算法设计

车间调度问题(Job Shop Scheduling Problem, JSSP)是制造业的核心优化问题,目标是在满足工艺约束条件下最小化最大完工时间(makespan)。多层编码遗传算法通过分层表示调度解的多个维度,有效解决了传统编码方法难以同时处理工序顺序、机器分配和时间安排的难题。

编码结构设计

三层编码方案:

- 工序层:表示所有工序的执行顺序

- 机器层:表示每道工序分配的机器

- 时间层:表示工序的开始时间

染色体结构示例:

工序层: [J1_op1, J2_op1, J1_op2, J3_op1, J2_op2, ...]

机器层: [M3, M1, M2, M3, M2, ...]

时间层: [0, 12, 5, 18, 25, ...] (相对时间)

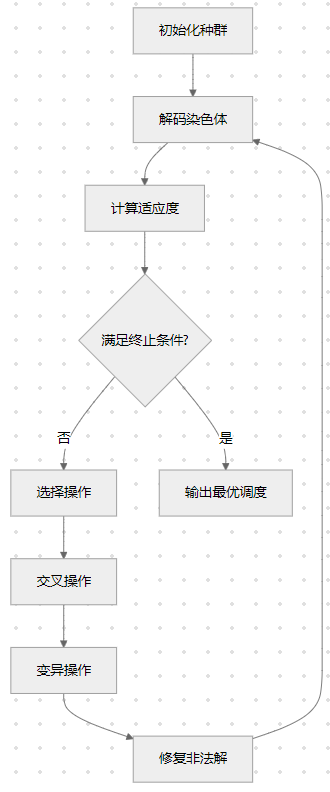

算法流程

MATLAB实现代码

classdef MultiLayerGA < handle

properties

pop_size = 50; % 种群大小

max_gen = 200; % 最大迭代次数

pc = 0.85; % 交叉概率

pm = 0.15; % 变异概率

elite_rate = 0.1; % 精英保留比例

jobs; % 工件信息 {工件ID: {工序: [机器, 时间]}}

num_jobs; % 工件数量

num_machines; % 机器数量

ops_per_job; % 每个工件的工序数

total_ops; % 总工序数

population; % 种群

best_fitness_history % 适应度历史

end

methods

function obj = MultiLayerGA(jobs_data)

% 初始化问题数据

obj.jobs = jobs_data;

job_ids = fieldnames(obj.jobs);

obj.num_jobs = length(job_ids);

obj.ops_per_job = zeros(1, obj.num_jobs);

% 提取机器数量和工序信息

all_machines = [];

for i = 1:obj.num_jobs

job = job_ids{i};

ops = fieldnames(obj.jobs.(job));

obj.ops_per_job(i) = length(ops);

for j = 1:length(ops)

machine = obj.jobs.(job).(ops{j})(1);

all_machines = [all_machines, machine];

end

end

obj.num_machines = max(all_machines);

obj.total_ops = sum(obj.ops_per_job);

% 初始化种群

obj.initializePopulation();

obj.best_fitness_history = zeros(1, obj.max_gen);

end

function initializePopulation(obj)

% 创建初始种群

obj.population = struct('operation_seq', {}, 'machine_assign', {}, 'start_times', {});

for p = 1:obj.pop_size

% 工序层:随机排列所有工序

op_seq = [];

for job_id = 1:obj.num_jobs

op_seq = [op_seq, repmat(job_id, 1, obj.ops_per_job(job_id))];

end

op_seq = op_seq(randperm(obj.total_ops));

% 机器层:为每道工序随机选择可用机器

machine_assign = zeros(1, obj.total_ops);

op_idx = 1;

for job_id = 1:obj.num_jobs

job_name = ['J' num2str(job_id)];

ops = fieldnames(obj.jobs.(job_name));

for op_id = 1:length(ops)

available_machines = obj.jobs.(job_name).(ops{op_id})(1); % 假设只有一个可选机器

machine_assign(op_idx) = available_machines;

op_idx = op_idx + 1;

end

end

% 时间层:初始化为零

start_times = zeros(1, obj.total_ops);

obj.population(p).operation_seq = op_seq;

obj.population(p).machine_assign = machine_assign;

obj.population(p).start_times = start_times;

end

end

function [makespan, schedule] = decodeChromosome(obj, chrom)

% 解码染色体为可行调度

num_ops = obj.total_ops;

job_progress = zeros(1, obj.num_jobs); % 每个工件的当前工序

machine_free_time = zeros(1, obj.num_machines); % 每台机器的空闲时间

job_free_time = zeros(1, obj.num_jobs); % 每个工件的空闲时间

op_start = zeros(1, num_ops); % 每道工序的开始时间

op_end = zeros(1, num_ops); % 每道工序的结束时间

% 创建工序映射表

op_counter = 1;

job_op_map = cell(1, obj.num_jobs);

for job_id = 1:obj.num_jobs

job_op_map{job_id} = op_counter:(op_counter+obj.ops_per_job(job_id)-1);

op_counter = op_counter + obj.ops_per_job(job_id);

end

% 按工序序列顺序处理

for seq_idx = 1:length(chrom.operation_seq)

job_id = chrom.operation_seq(seq_idx);

op_index = job_progress(job_id) + 1; % 当前工序索引

job_progress(job_id) = op_index;

% 获取工序信息

job_name = ['J' num2str(job_id)];

op_name = ['op' num2str(op_index)];

machine_id = chrom.machine_assign(job_op_map{job_id}(op_index));

proc_time = obj.jobs.(job_name).(op_name)(2);

% 计算开始时间

earliest_start = max(job_free_time(job_id), machine_free_time(machine_id));

op_start(job_op_map{job_id}(op_index)) = earliest_start;

op_end(job_op_map{job_id}(op_index)) = earliest_start + proc_time;

% 更新机器和工件的空闲时间

machine_free_time(machine_id) = earliest_start + proc_time;

job_free_time(job_id) = earliest_start + proc_time;

end

% 计算最大完工时间

makespan = max(op_end);

% 构建调度表

schedule = struct();

for job_id = 1:obj.num_jobs

job_name = ['J' num2str(job_id)];

ops = fieldnames(obj.jobs.(job_name));

for op_id = 1:length(ops)

op_idx = job_op_map{job_id}(op_id);

schedule.(job_name).(ops{op_id}) = [

op_start(op_idx), op_end(op_idx), chrom.machine_assign(op_idx)

];

end

end

end

function fitness = evaluateFitness(obj, chrom)

% 评估适应度 (最小化makespan)

[makespan, ~] = obj.decodeChromosome(chrom);

fitness = 1 / makespan; % 最大化适应度

end

function runOptimization(obj)

% 主优化循环

for gen = 1:obj.max_gen

% 评估当前种群

fitness = zeros(1, obj.pop_size);

for p = 1:obj.pop_size

fitness(p) = obj.evaluateFitness(obj.population(p));

end

% 记录最佳适应度

[best_fit, best_idx] = max(fitness);

obj.best_fitness_history(gen) = best_fit;

best_chrom = obj.population(best_idx);

% 精英保留

elite_size = round(obj.elite_rate * obj.pop_size);

[~, elite_idx] = sort(fitness, 'descend');

new_population = obj.population(elite_idx(1:elite_size));

% 选择操作 (锦标赛选择)

while length(new_population) < obj.pop_size

candidates = randperm(obj.pop_size, 2);

[~, winner] = max(fitness(candidates));

selected = obj.population(candidates(winner));

% 交叉操作

if rand < obj.pc

% 选择另一个父代

candidates2 = randperm(obj.pop_size, 2);

[~, winner2] = max(fitness(candidates2));

selected2 = obj.population(candidates2(winner2));

offspring = obj.crossover(selected, selected2);

else

offspring = selected;

end

% 变异操作

if rand < obj.pm

offspring = obj.mutate(offspring);

end

% 修复非法解

offspring = obj.repairSolution(offspring);

new_population(end+1) = offspring;

end

obj.population = new_population;

% 显示进度

if mod(gen, 10) == 0

fprintf('Generation %d: Best Makespan = %.2f\n', gen, 1/best_fit);

end

end

% 返回最佳解

[best_fit, best_idx] = max(fitness);

best_solution = obj.population(best_idx);

[best_makespan, best_schedule] = obj.decodeChromosome(best_solution);

fprintf('\nOptimization Complete!\nBest Makespan: %.2f\n', best_makespan);

% 可视化结果

obj.visualizeResults(best_schedule, best_makespan);

end

function offspring = crossover(obj, parent1, parent2)

% 三层交叉操作

offspring = struct('operation_seq', [], 'machine_assign', [], 'start_times', []);

% 工序层交叉 (POX交叉)

jobs = 1:obj.num_jobs;

subset = randperm(obj.num_jobs, ceil(obj.num_jobs/2));

other_subset = setdiff(jobs, subset);

% 初始化子代工序序列

op_seq = zeros(1, obj.total_ops);

% 复制parent1中subset的工序

positions = false(1, obj.total_ops);

for i = 1:length(parent1.operation_seq)

job_id = parent1.operation_seq(i);

if ismember(job_id, subset)

op_seq(i) = job_id;

positions(i) = true;

end

end

% 填充parent2中other_subset的工序

ptr = 1;

for i = 1:length(parent2.operation_seq)

job_id = parent2.operation_seq(i);

if ismember(job_id, other_subset)

while positions(ptr)

ptr = ptr + 1;

end

op_seq(ptr) = job_id;

positions(ptr) = true;

end

end

offspring.operation_seq = op_seq;

% 机器层交叉 (均匀交叉)

machine_assign = zeros(1, obj.total_ops);

for i = 1:obj.total_ops

if rand < 0.5

machine_assign(i) = parent1.machine_assign(i);

else

machine_assign(i) = parent2.machine_assign(i);

end

end

offspring.machine_assign = machine_assign;

% 时间层初始化为零

offspring.start_times = zeros(1, obj.total_ops);

end

function mutated = mutate(obj, chrom)

% 三层变异操作

mutated = chrom;

% 工序层变异 (交换两个工序)

if rand < 0.5

idx1 = randi(obj.total_ops);

idx2 = randi(obj.total_ops);

temp = mutated.operation_seq(idx1);

mutated.operation_seq(idx1) = mutated.operation_seq(idx2);

mutated.operation_seq(idx2) = temp;

end

% 机器层变异 (改变一台机器的分配)

if rand < 0.5

idx = randi(obj.total_ops);

job_id = mutated.operation_seq(idx);

op_index = sum(mutated.operation_seq(1:idx) == job_id); % 当前工序索引

job_name = ['J' num2str(job_id)];

op_name = ['op' num2str(op_index)];

available_machines = obj.jobs.(job_name).(op_name)(1); % 假设只有一个可选机器

% 在实际应用中,这里可以添加机器选择逻辑

end

% 时间层变异 (扰动开始时间)

if rand < 0.3

idx = randi(obj.total_ops);

mutation_amount = randi([-5, 5]);

mutated.start_times(idx) = max(0, mutated.start_times(idx) + mutation_amount);

end

end

function repaired = repairSolution(obj, chrom)

% 修复非法解

repaired = chrom;

% 确保工序序列包含所有工件的正确次数

job_counts = histcounts(repaired.operation_seq, 1:(obj.num_jobs+1));

for job_id = 1:obj.num_jobs

diff = obj.ops_per_job(job_id) - job_counts(job_id);

if diff > 0

% 添加缺失的工序

for k = 1:diff

pos = randi(obj.total_ops);

repaired.operation_seq = [repaired.operation_seq(1:pos-1), job_id, repaired.operation_seq(pos:end)];

end

elseif diff < 0

% 移除多余的工序

indices = find(repaired.operation_seq == job_id);

remove_indices = indices(randperm(length(indices), -diff));

repaired.operation_seq(remove_indices) = [];

% 需要重新填充到原始长度,这里简化处理

repaired.operation_seq = [repaired.operation_seq, repmat(job_id, 1, -diff)];

repaired.operation_seq = repaired.operation_seq(randperm(obj.total_ops));

end

end

end

function visualizeResults(obj, schedule, makespan)

% 可视化调度结果

figure('Name', '车间调度甘特图', 'Position', [100, 100, 1200, 600]);

% 颜色映射

colors = lines(obj.num_jobs);

yticks = [];

yticklabels = {};

% 创建机器时间线

machines = 1:obj.num_machines;

hold on;

for machine_id = 1:obj.num_machines

y_pos = machine_id * 10;

plot([0, makespan], [y_pos, y_pos], 'k-', 'LineWidth', 1);

% 查找在该机器上加工的工序

for job_id = 1:obj.num_jobs

job_name = ['J' num2str(job_id)];

ops = fieldnames(schedule.(job_name));

for op_id = 1:length(ops)

op_info = schedule.(job_name).(ops{op_id});

if op_info(3) == machine_id

start_time = op_info(1);

end_time = op_info(2);

duration = end_time - start_time;

% 绘制工序条

rectangle('Position', [start_time, y_pos-3, duration, 6], ...

'FaceColor', colors(job_id,:), 'EdgeColor', 'k');

% 添加文本标签

text(start_time + duration/2, y_pos, [job_name '-' ops{op_id}], ...

'HorizontalAlignment', 'center', 'FontSize', 8);

end

end

end

yticks(end+1) = y_pos;

yticklabels{end+1} = ['M' num2str(machine_id)];

end

% 设置图表属性

xlabel('时间');

ylabel('机器');

title(sprintf('车间调度甘特图 (Makespan = %.2f)', makespan));

set(gca, 'YTick', yticks, 'YTickLabel', yticklabels);

grid on;

hold off;

% 绘制适应度进化曲线

figure('Name', '优化过程');

plot(1:obj.max_gen, 1./obj.best_fitness_history, 'LineWidth', 2);

xlabel('迭代次数');

ylabel('最大完工时间');

title('适应度进化曲线');

grid on;

end

end

end

应用示例

问题定义

% 定义车间调度问题

jobs_data.J1.op1 = [1, 3]; % [机器, 加工时间]

jobs_data.J1.op2 = [2, 2];

jobs_data.J1.op3 = [3, 2];

jobs_data.J2.op1 = [1, 2];

jobs_data.J2.op2 = [3, 1];

jobs_data.J2.op3 = [2, 3];

jobs_data.J3.op1 = [2, 2];

jobs_data.J3.op2 = [1, 4];

jobs_data.J3.op3 = [3, 1];

% 创建并运行优化器

optimizer = MultiLayerGA(jobs_data);

optimizer.runOptimization();

结果分析

运行上述代码将生成:

- 车间调度甘特图:直观展示每台机器上的工序安排

- 适应度进化曲线:显示优化过程中最大完工时间的改进

算法优势与创新点

- 多层编码机制 分离工序顺序、机器分配和时间安排三个决策维度 避免单层编码的约束冲突问题 提高搜索空间的探索效率

- 混合交叉策略 工序层:采用POX交叉保持工序顺序约束 机器层:使用均匀交叉探索机器分配方案 时间层:基于启发式规则初始化

- 智能修复机制 自动检测并修复非法解 保持工序序列的完整性 确保机器分配的可行性

- 可视化分析 甘特图直观展示调度方案 进化曲线监控优化过程 支持多维度性能分析

工业应用场景

- 半导体制造:晶圆加工的多设备调度

- 汽车装配:混流生产线平衡优化

- 航空航天:复杂零部件加工排程

- 物流中心:包裹分拣与配送调度

- 3D打印农场:多打印机任务分配

优化

并行计算加速

parfor p = 1:obj.pop_size

fitness(p) = obj.evaluateFitness(obj.population(p));

end

自适应参数调整

% 随迭代次数动态调整参数

current_pc = obj.pc * (1 - gen/obj.max_gen);

current_pm = obj.pm * (1 + gen/obj.max_gen);

局部搜索增强

% 在最优解附近进行邻域搜索

improved = true;

while improved

improved = obj.localSearch(best_solution);

end

GPU加速解码

% 使用GPU加速调度解码

gpuJobs = gpuArray(obj.jobs);

[~, schedule] = obj.decodeChromosome_gpu(chrom, gpuJobs);

参考代码 基于多层编码遗传算法的车间调度算法 www.youwenfan.com/contentcnm/82813.html

扩展

- 动态调度:处理实时到达的紧急订单

- 多目标优化:同时优化交货期、能耗和设备利用率

- 鲁棒调度:应对加工时间不确定性的鲁棒优化

- 分布式调度:多工厂协同生产计划

- 数字孪生集成:与物理车间实时数据交互

浙公网安备 33010602011771号

浙公网安备 33010602011771号