L3 设计,开发,认证

L3 设计,开发,认证

这里我暂时跳过了那些PPT里面要求看的视频,过一会再整理。

利益相关者和需求

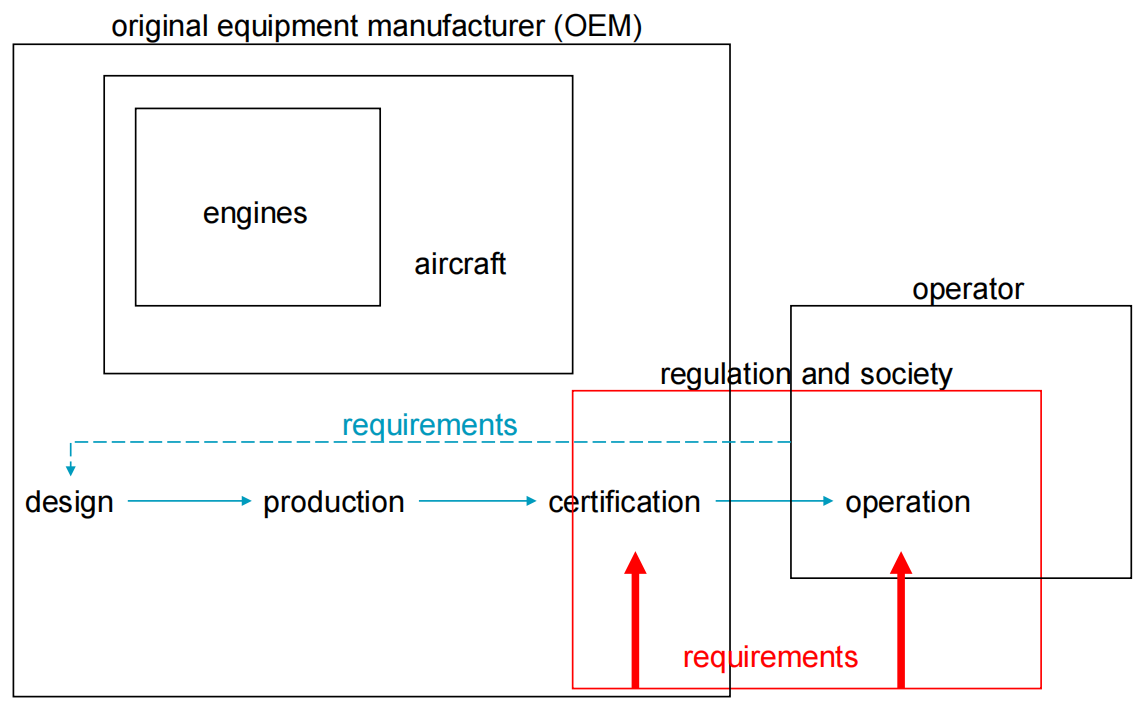

从图中我们可以得到如下信息:

- 航空器的生命周期:设计——生产——认证——运营

- 原始设备制造商(original equipment manufacturer,OEM):负责飞机的设计、生产和认证,其中发动机虽然也是飞机制造体系的一部分,但通常由专门的发动机制造商负责;

他们在设计阶段接受运营方的需求,并在认证阶段接受监管和社会要求。 - 运营方(Operator):航空公司和其他使用航空器的组织,负责飞机的运营,在运营中接受监管和社会要求,并把运营中产生的新需求提交给制造商。

- 监督和社会(regulation and society):监管机构制定法规和要求,社会通过舆论等方式影响航空业。

它们主要作为利益相关者,参与认证和运营阶段。

From the image, we can gather the following information:

- Aircraft lifecycle: Design -> Production -> Certification -> Operation

- Original Equipment Manufacturer (OEM): Responsible for the design, production, and certification of the aircraft. Although the engine is also a part of the aircraft manufacturing system, it is typically handled by a specialized engine manufacturer.

They accept the operator's requirements during the design phase and regulatory and societal requirements during the certification phase. - Operator: Airlines and other organizations using the aircraft, responsible for the operation of the aircraft. They accept regulatory and societal requirements during operations and submit new operational requirements to the manufacturer.

- Regulation and Society: Regulatory bodies set regulations and requirements, and society influences the aviation industry through public opinion and other means.

They primarily act as stakeholders, participating in the certification and operation phases.

设计与开发的过程计划

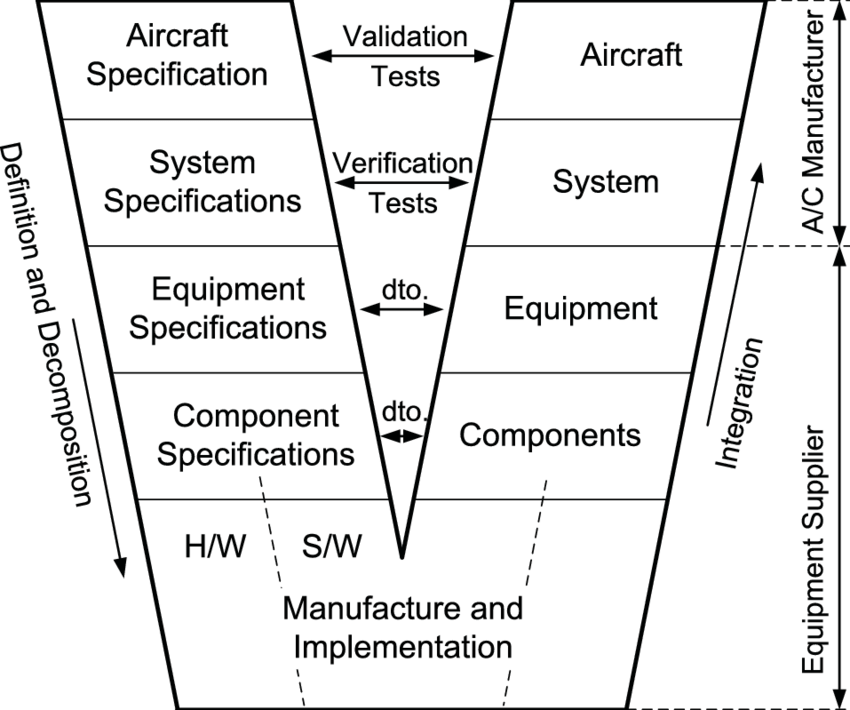

下面这张图是一个“V”字模型,是系统工程中常用的开发流程模型。

其主要流程为:

- 左侧:定义和分解(definition and decomposition),从最顶层的航空器需求开始,逐级向下分解到系统级、设备级、组件级,每一层都有明确对应的需求或规范(specification)。

- 底部:制造与实现(manufacture and implementation),在需求分解完成后,进行物理硬件生产,以及软件系统开发。

- 右侧:集成、验证和确认(integration, verification and validation),逐级往上进行集成测试,和各级规格对比;

组件级和部件级由设备提供商进行,系统级和航空器级由航空器整机制造商进行;

在系统级,需要进行验证,检查产品是否“做对了”,即是否满足设计要求;

在航空器层面,需要确认“是否做对的产品”,即产品能否满足最初定义的任务和用户运营需求。

The main process is as follows:

- Left side: Definition and Decomposition, starting from the top-level aircraft requirements and progressively breaking down to the system level, equipment level, and component level. Each layer has clear corresponding requirements or specifications.

- Bottom: Manufacture and Implementation, after the requirements decomposition is complete, physical hardware production and software system development are carried out.

- Right side: Integration, Verification, and Validation, progressively integrating and testing, and comparing with the specifications at each level;

Component and equipment levels are handled by equipment suppliers, while system and aircraft levels are handled by the aircraft manufacturer;

At the system level, verification is required to check if the product is "done correctly," i.e., whether it meets design requirements;

At the aircraft level, confirmation is required to determine whether the "right product" has been made, i.e., whether the product can meet the initially defined tasks and user operational requirements.

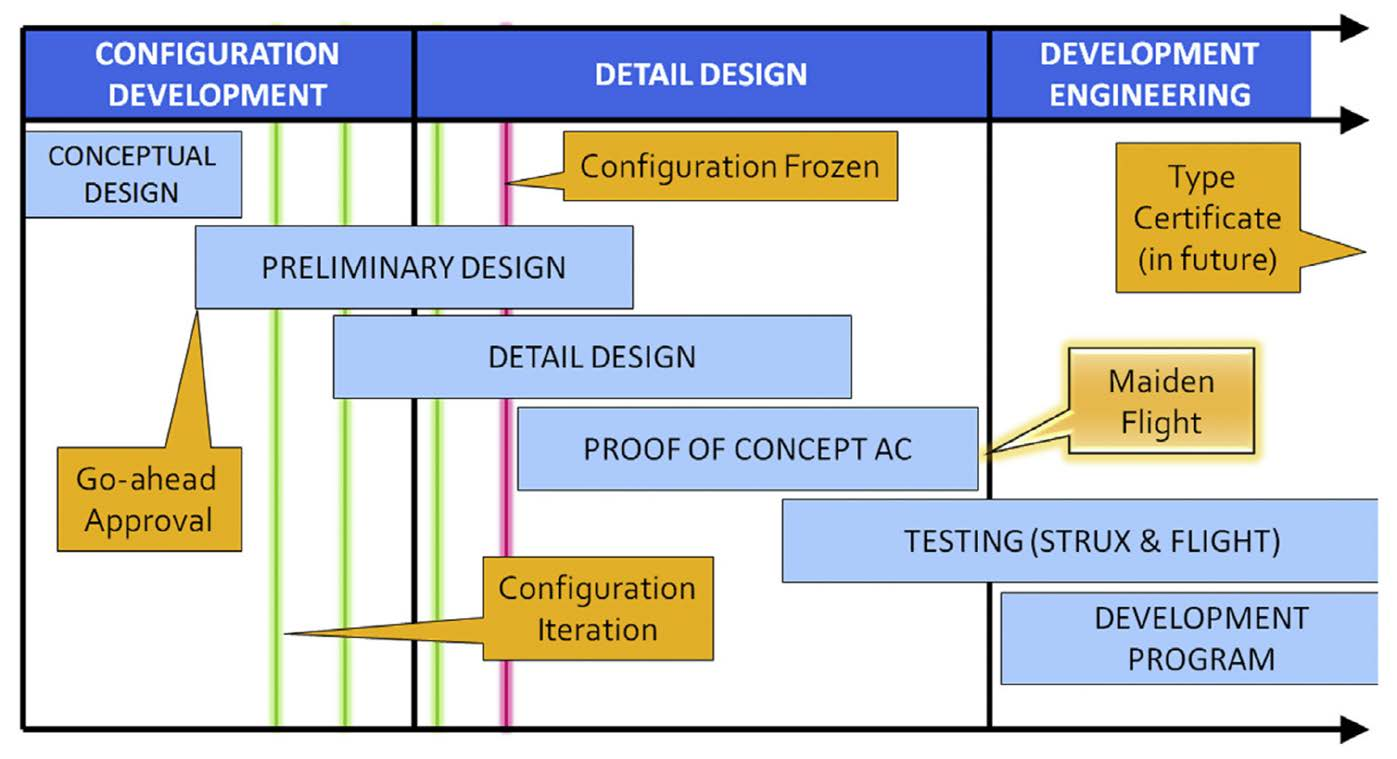

下面这张图则展示了飞机研发阶段的流程划分,想必大伙一定对徐老师的1003这门课有深刻的印象,都是老熟人。

阶段划分如下:

-

构型开发

- 概念设计(conceptual design):

评估市场需求、技术可行性、经济性等,定义总体方案,如飞机类型、航程、座位、发动机初步型号。

在概念设计大部分完成时,企业进行启动批准(go-ahead approval),根据商业和技术可行性,决定是否进入下一个阶段。 - 初步设计(preliminary design):

细化飞机外形、结构、主要系统布置,如机身和机翼气动外形初步设计,重心平衡,飞控、航电、动力系统选型。

在初步设计阶段,会进行多次迭代,对飞机主要参数和构型进行优化。

- 概念设计(conceptual design):

-

详细设计

- 详细设计:

在初步设计部分完成时展开,对飞机的每个系统、部件、零件进行具体设计,包括结构设计、材料选择、生产工艺、装配方案等,输出详细工程图纸和制造指令。

(喜欢我bug频出的3DExperience机床模拟吗)

注意,由于初步设计和详细设计在部分阶段是同时进行的,这样飞机主要参数和构型的迭代也会要求详细设计跟着迭;

在初步设计的最后阶段、详细设计的中间阶段,将确定最终构型,冻结主要气动、结构、其他系统方案;

此时初步设计还会延伸一点,详细设计将基于冻结的构型继续工作。 - 概念验证机(proof of concept AC):

基于设计方案,制造验证机或原型机,在真实环境下验证关键技术,并测试设计的可行性。

例如F-22的原型机YF-22,钻石机翼、隐身外形、二维推力矢量、先进飞控和座舱布局,这些F22的重要设计元素都有,但它装配了两台不同的发动机进行测试,此外F-22相比其原型机进行了一些修改,包括减小全动尾翼面积、减少主翼和尾翼的后掠角、修改机翼和机身的形状以改善气动和隐身特性等,以及其他系统布局和结构设计的改进。

它从方案冻结开始,和详细设计阶段共同工作,并将持续到详细设计完成后,直到真机首飞(maiden flight)为止。

- 详细设计:

-

研制工程(development engineering)

- 首飞:这是飞机进入研制工程阶段的标志。

- 测试:

一个是STRUX(结构测试,structural testing),包括静力试验、疲劳试验等,比如说把一个飞机的机翼猛猛往上拉,看它在多大的载荷下会断掉。

下图展示了C919客机的静力测试机进行试验的情况,注意右翼。

![image]()

另一个就是首飞后的飞行测试,验证飞机实际飞行性能、系统功能等。

比如歼10试飞的时候,为了摸飞机的极限,大迎角失速-尾旋改出试飞这种危险科目都是要做的。(向试飞员致敬) - 发展/研制项目:结合测试结果,进行一系列的改进。

- 取得型号合格证:通过航空监管机构(如FAA、EASA等)的适航认证后,飞机会获得型号合格证(Type Certificate),可以进入商业运营或量产阶段。

-

Configuration Development

- Conceptual Design:

Assess market demand, technical feasibility, economics, etc., to define the overall plan, such as aircraft type, range, seating, and preliminary engine model.

When most of the conceptual design is complete, the company proceeds with a go-ahead approval to decide whether to move to the next phase based on commercial and technical feasibility. - Preliminary Design:

Refine the aircraft's appearance, structure, and primary system layout, such as preliminary aerodynamic design of the fuselage and wings, center of gravity balance, flight control, avionics, and power system selection.

During the preliminary design phase, multiple iterations will take place to optimize the aircraft's key parameters and configuration.

- Conceptual Design:

-

Detailed Design

- Detailed Design:

After completing the preliminary design phase, specific design work for every system, part, and component of the aircraft is undertaken, including structural design, material selection, production processes, assembly plans, etc., resulting in detailed engineering drawings and manufacturing instructions.

(Do you like my bug-prone 3DExperience machine tool simulations?)

Note that due to the overlap between the preliminary design and detailed design phases, iteration of key parameters and configurations will also require the detailed design to follow suit.

At the final stage of the preliminary design and the intermediate stage of the detailed design, the final configuration is confirmed, and key aerodynamic, structural, and other system plans are frozen.

At this point, the preliminary design extends slightly, and the detailed design continues based on the frozen configuration. - Proof of Concept Aircraft (POC AC):

Based on the design plan, a prototype or proof of concept aircraft is manufactured to validate key technologies and test the feasibility of the design in a real-world environment.

For example, the F-22 prototype YF-22, featuring diamond-shaped wings, stealthy shape, two-dimensional thrust vectoring, advanced flight controls, and cockpit layout, had these critical design elements but was tested with two different engines.

In addition to this, the F-22 incorporated modifications from its prototype, including reducing the area of the all-moving tail, reducing the sweep angle of the main wing and tail, and reshaping the wing and fuselage to improve aerodynamics and stealth features, as well as other system layouts and structural design improvements.

The proof of concept phase starts from the design freeze and works alongside the detailed design phase until the maiden flight of the aircraft.

- Detailed Design:

-

Development Engineering

- Maiden Flight: This marks the entry of the aircraft into the development engineering phase.

- Testing:

One type is STRUX (Structural Testing), which includes static tests, fatigue tests, etc., such as pulling an aircraft's wing upward forcefully to see at what load it would break.

The image below shows the static test rig for the C919 passenger aircraft during testing, with the right wing clearly visible.

Another type is flight testing after the maiden flight to validate the aircraft's actual flying performance, system functionality, etc.

For example, during J-10's test flights, to push the aircraft's limits, dangerous maneuvers like high angle-of-attack stalls and tail spins were performed. (Salute to the test pilots!) - Development/Manufacturing Projects: Based on the testing results, a series of improvements are made.

- Type Certification: After receiving airworthiness certification from aviation regulatory bodies (e.g., FAA, EASA), the aircraft receives its type certificate and can proceed to commercial operation or mass production.

另一种简单概述一个新机型的设计与开发过程的描述如下:

- 概念化和市场分析

- 初步设计阶段

- 详细设计阶段

- 原型构建

- 飞行测试和认证

- 生产爬坡和认证

- 客户交付和服务进入

Another simple description of the design and development process of a new model is as follows:

- Conceptualization and market analysis

- Preliminary design stage

- Detailed design stage

- Prototype construction

- Flight testing and certification

- Production ramp-up and certification

- Customer delivery and service entry

适航性和认证

适航性

概念:

适航性(airworthiness,注意这里后面还有一个i)指飞机、飞机发动机或其他航空产品,在飞行中能够安全地执行器预期功能的状态,这种状态需要持续保持,并受到监管机构的监管。

它涉及如下方面:

- 符合监管要求和设计标准,由各国或国际航空管理机构规定。

- 遵循规定的维护程序和周期,定期对飞机进行检查、维修和必要的升级,确保飞机在全寿命周期内,持续符合安全标准。

- 航空认证机构(如FAA,Federal Aviation Administration,联邦航空管理局,美国的航空认证机构)作为在其管辖范围内监管飞机设计、生产、运营的政府/准政府组织,负责制定法规、颁发证书、进行检查,并监督在管辖范围内运营的飞机的适航性。

Concept:

Airworthiness refers to the state in which an aircraft, aircraft engine or other aviation products can safely perform their intended functions during flight. This state must be maintained continuously and is subject to the supervision of regulatory authorities.

It involves the following aspects:

- Comply with regulatory requirements and design standards as stipulated by national or international aviation management authorities.

- Follow prescribed maintenance procedures and cycles, conducting regular inspections, repairs, and necessary upgrades to aircraft to ensure they continuously meet safety standards throughout their entire life cycle.

- Aviation certification authorities (such as the FAA, Federal Aviation Administration, the aviation certification authority of the United States) act as government or quasi-government organizations that regulate aircraft design, production, and operation within their jurisdiction. They are responsible for formulating regulations, issuing certificates, conducting inspections, and supervising the airworthiness of aircraft operating within their jurisdiction.

认证流程

接下来简要介绍一下商业飞机获得型号认证的一般步骤。

- 设计和开发:

飞机制造商根据航空管理部门的标准和规定,设计和开发飞机。

通过工程工作、测试和分级,确保飞机符合安全、性能、适航性要求。 - 型号认证申请:

飞机制造商向监管机构递交型号认证申请,包括飞机设计、制造、系统、性能特点,以及符合相关法规、标准的详细文件。 - 申请前会议

- 认证基础:

监管机构列出制造商必须满足的特定法规、标准、要求,以获取型号认证。 - 技术文件提交:

制造商准备并提交技术文件给监管机构,以证明产品符合认证基础,通常包括详细的设计数据、测试报告、分析结果和安全评估。

(就怕他把这个东西跟seminar联系起来考,那就麻爪了) - 型号检查:

监管机构对飞机和文件进行检查与评估,验证其是否符合认证基础,这可能包括访问制造商设施,并审查测试结果和工程数据。 - 型号认证委员会审查:

监管机构内部的型号认证委员会或小组开展,综合各领域专家意见,审查技术文件、检查结果和其他信息,以确定飞机符合型号认证要求。 - 型号证书发放:监管机构为符合所有适用的要求的飞机发放型号证书,指定飞机型号设计、限制条件及其他细节,认证其适航性,授权其在本区域商业运营中使用。

- 持续适航性:制造商和运营商持续履行维护、检查和报告义务,遵守持续适航性要求。

- 型号证书验证:飞机制造商寻求其他国家或地区的监管机构验证型号证书,以在国际市场销售飞机。

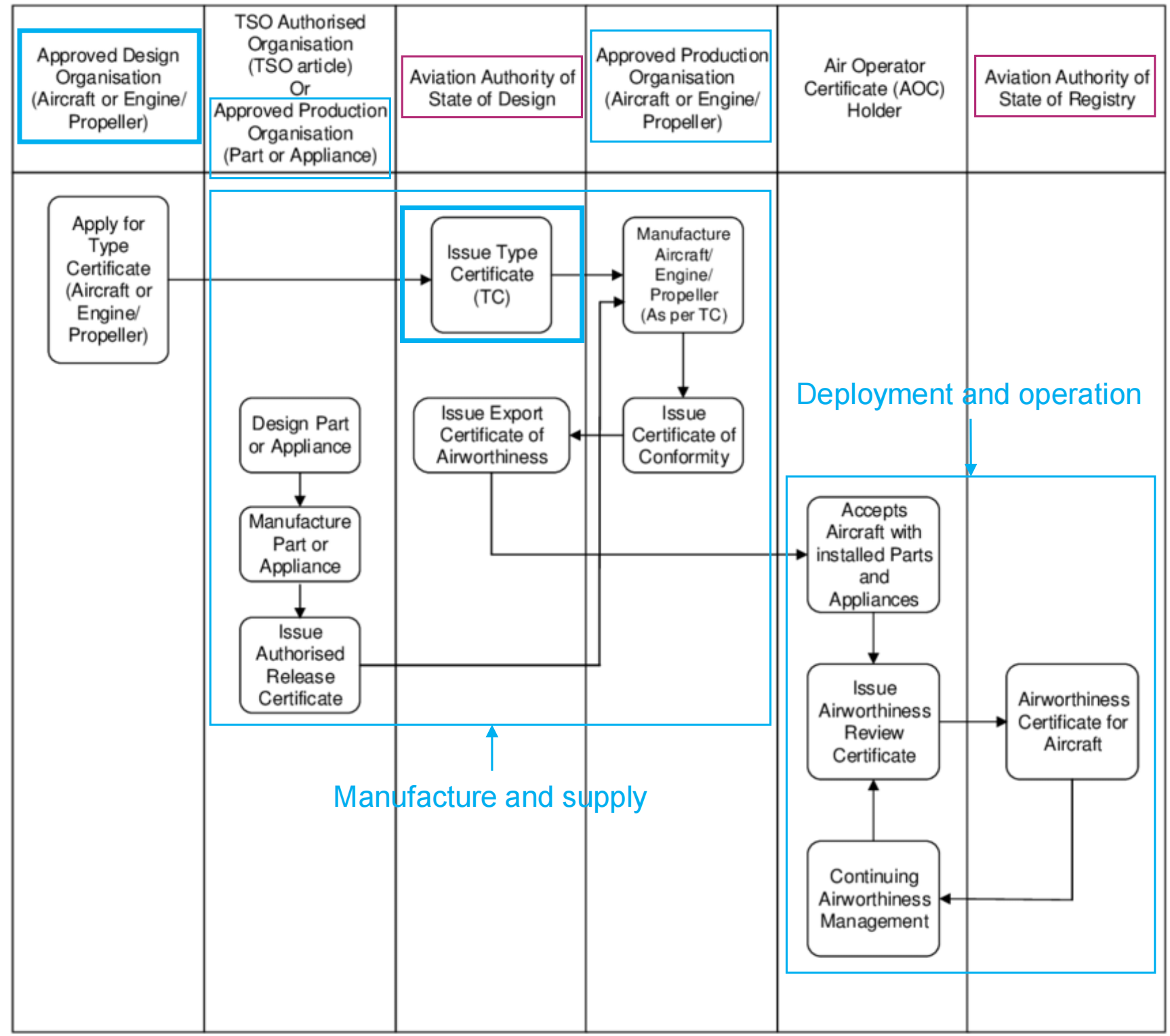

下面这张图描述了一个航空产品(飞机、发动机、螺旋桨等)从设计、生产、交付到运营和维护的完整生命周期中,各个关键环节的认证流程。

Next, a brief introduction to the general steps for a commercial aircraft to obtain type certification will be given.

- Design and Development:

Aircraft manufacturers design and develop aircraft in accordance with the standards and regulations of aviation authorities.

Through engineering work, testing, and classification, they ensure that the aircraft meet safety, performance, and airworthiness requirements. - Type Certification Application:

Aircraft manufacturers submit type certification applications to regulatory authorities, including detailed documentation on aircraft design, manufacturing, systems, performance characteristics, and compliance with relevant regulations and standards. - Pre-Application Meeting

- Certification Basis:

Regulatory authorities list the specific regulations, standards, and requirements that manufacturers must meet to obtain type certification. - Submission of Technical Documentation:

Manufacturers prepare and submit technical documentation to regulatory authorities to prove that the product meets the certification basis, typically including detailed design data, test reports, analysis results, and safety assessments. - Type Inspection:

Regulatory authorities inspect and evaluate the aircraft and documentation to verify compliance with the certification basis. This may involve visiting manufacturing facilities and reviewing test results and engineering data. - Review by Type Certification Committee:

An internal type certification committee or team within the regulatory authority conducts a review, integrating expert opinions from various fields, to examine technical documentation, inspection results, and other information to determine if the aircraft meets type certification requirements. - Issuance of Type Certificate:

Regulatory authorities issue type certificates to aircraft that meet all applicable requirements, specifying the aircraft model design, limitations, and other details, certifying its airworthiness and authorizing its use in commercial operations within the region. - Continuing Airworthiness:

Manufacturers and operators continuously fulfill maintenance, inspection, and reporting obligations and comply with continuing airworthiness requirements. - Validation of Type Certificate:

Aircraft manufacturers seek validation of the type certificate from regulatory authorities in other countries or regions to sell aircraft in international markets.

The following picture depicts the certification process of each key stage in the complete life cycle of an aviation product (such as aircraft, engines, propellers, etc.) from design, production, delivery to operation and maintenance.

-

初始:经批准的飞机/发动机/螺旋桨设计商申请型号认证。

-

制造和供应:

- 由TSO(Technical Standard Order,技术标准规范,针对特定部件或设备)授权的,或经批准的(获航空管理机构认证,覆盖了整个生产组织及其质量管理体系)生产组织进行,设计、制造部件或设备,并签发授权放行证书(Issue Authorised Release Certificate),证明其可以交付给生产组织或运营商。

- 设计国航空管理机构(Aviation Authority of State of Design)进行认证,主要包括型号认证(type certificate, TC)和出口适航证(export certificate of airworthiness,证明其符合出口国的适航要求)。

- 经批准的生产组织根据型号认证和授权放行证书,制造飞机/发动机/螺旋桨,并在产品生产完成后进行质量检验,确认符合设计要求后签发合格证书(certificate of conformity),证明其可以交付给运营商。

这里需要注意的是,只有生产组织签发了产品合格证之后,航空管理机构才能给颁发出口适航证。

-

部署和运营(deployment and operation):

- 航空运营人执照(air operator certificate,AOC)持有人接受装好了部件和设备的飞机,申请适航证,并进行持续的适航性管理;

- 注册国航空主管部门(aviation authority of state of registry)颁发适航证,并监督持续适航管理。

-

Initial: The approved aircraft/engine/propeller design manufacturer applies for type certification.

-

Manufacturing and Supply:

- The design, manufacture of components or equipment, and issuance of the Authorized Release Certificate (ARC), which certifies that they can be delivered to the production organization or operator, are carried out by the production organization authorized by the TSO (Technical Standard Order) or approved (certified by the aviation authority, covering the entire production organization and its quality management system).

- The Aviation Authority of the State of Design conducts certification, mainly including type certification (TC) and export certificate of airworthiness (proving compliance with the airworthiness requirements of the exporting country).

- The approved production organization manufactures aircraft/engines/propellers based on type certification and the ARC, and conducts quality inspections after product production.

After confirming compliance with design requirements, it issues a certificate of conformity, certifying that they can be delivered to the operator.

It should be noted that only after the production organization issues the product conformity certificate can the aviation authority issue the export certificate of airworthiness.

-

Deployment and operation:

- The holder of an air operator certificate (AOC) accepts the aircraft with installed components and equipment, applies for an airworthiness certificate, and conducts continuous airworthiness management;

- the aviation authority of the state of registry issues the airworthiness certificate and supervises the continuous airworthiness management.

浙公网安备 33010602011771号

浙公网安备 33010602011771号