L1 通讲

L1 通讲

部分知识点速通

技术与产品开发的动机

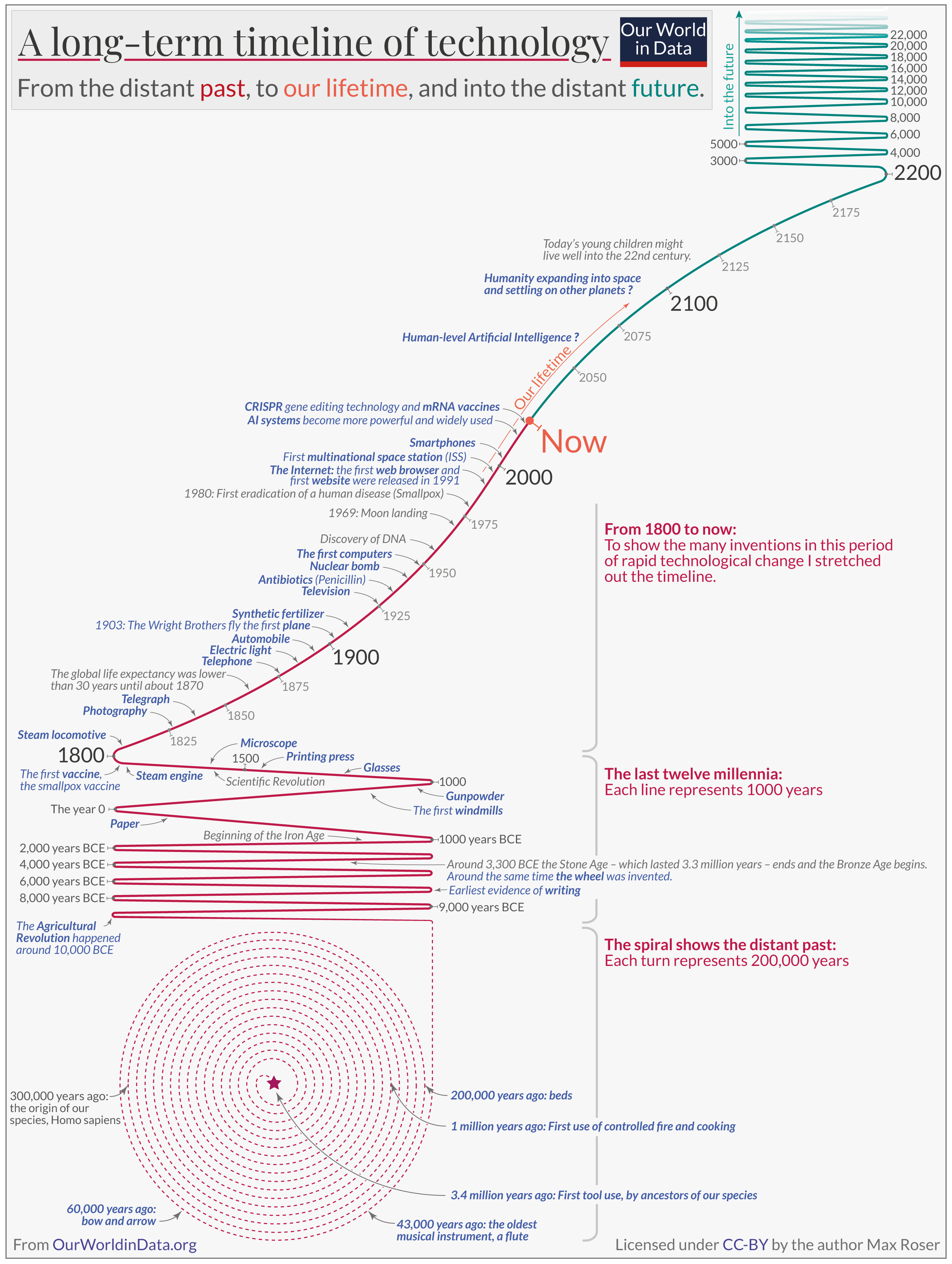

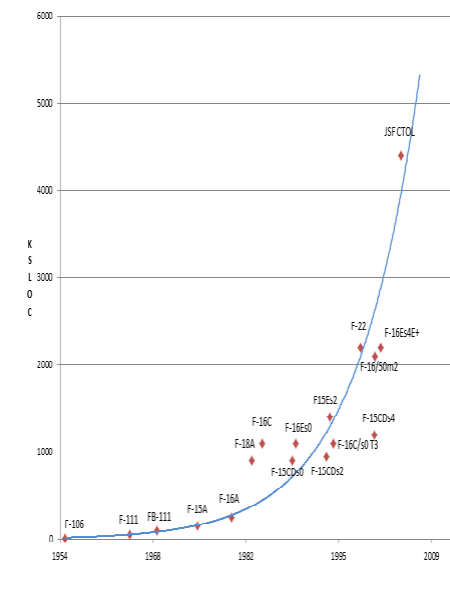

这张图展示了两个长期趋势:

- 技术和创新的发展速度逐渐变快;

它对我们的生活影响非常广泛,包括好的(如天花疫苗)和坏的(核弹?) - 技术变得越来越强大。

例如,我们的祖先使用石制工具,但现在我们构建跨越全球的ai系统,和基因编辑技术。

最新技术,例如人工智能,为其控制者赋予了巨大的力量,而且它甚至有脱离我们控制的风险。因此,哪些技术、被谁控制,是当今最重要的政治问题之一,它不仅仅是技术专家的问题。

This chart shows two long-term trends:

- The pace of technological and innovative development is gradually accelerating; its influence on our lives is very extensive, including both the good (such as the smallpox vaccine) and the bad (nuclear bombs?).

- Technology is becoming increasingly powerful. For instance, our ancestors used stone tools, but now we build AI systems spanning the globe and develop gene editing technologies.

The latest technologies, such as artificial intelligence, have endowed their controllers with immense power, and there is even a risk that they might slip out of our control. Therefore, which technologies and who controls them are among the most important political issues today, and they are not just the concern of technical experts.

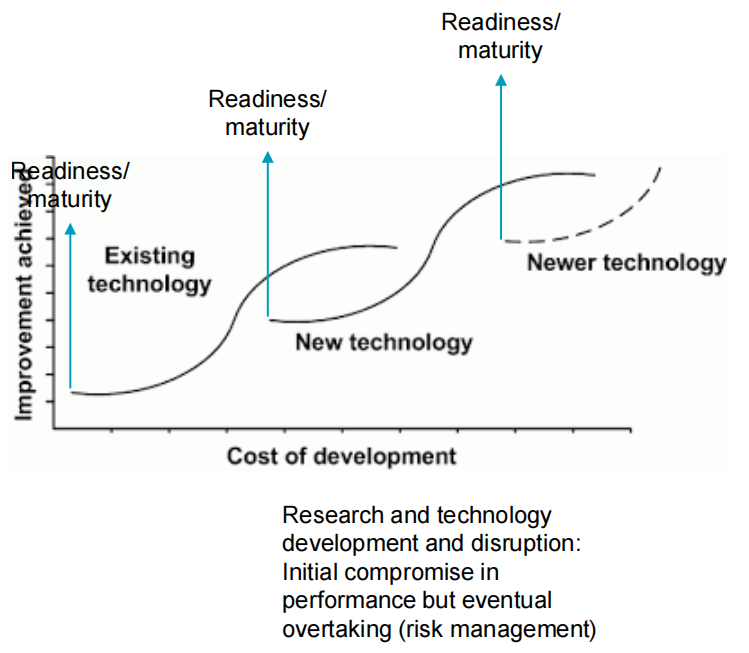

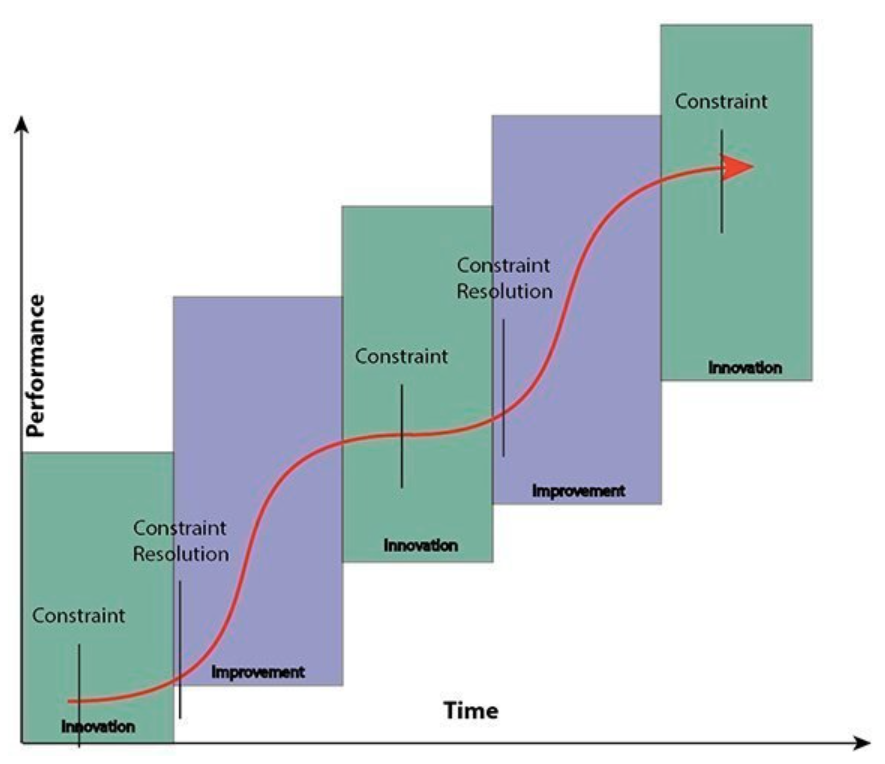

这里主要讲述了“S曲线”,参考下图。

S曲线代表了一种基本模式:由于正反馈循环,曲线加速,然后由于约束而减速;

当约束被打破时,正反馈循坏再次加速,直到遇到另一个约束。

技术创新的曲线可以说明如下事实:

- 低谷期:当现有技术S曲线成熟或趋于饱和时,颠覆性创新开始出现。

这一创新往往专注于一些特定的、不是当前主流需求的性能特征,但能满足某些用户群体的独特需求。

但新技术的总体初始性能较低,甚至不如现有技术,这会使得主导现有技术的公司对颠覆性创新进行早期投资的决策“显得”不那么合理。 - 快速增长期:随着研发投入增加,技术加速发展,性能显著上升,最终超越现有技术。

随着技术进步和用户偏好的变化,原本不是主流的性能特征成为了市场的新焦点,新技术的独特优势开始满足或超越用户的新需求,推动其从边缘市场进入主流。

还有一种创新进步:降低该特定维度性能,但提高了其他维度性能(例如灵活性降低,但更易于部署和使用),这样也算对原始创新的“颠覆”。 - 成熟期:技术发展趋于平缓,性能提升空间有限,进一步改进的边际效益递减,曲线接近顶点。

- 需要注意的是,颠覆性创新从低谷到超越的过程需要有效的风险管理。

早期性能妥协意味着新技术可能面临市场接受度低或投资回报周期长的挑战,而成功的颠覆依赖于研发策略的优化和市场时机的把握。

例如,人工智能在早期发展中,其稳定性不如传统算法,但在模式识别和数据处理方面展现出潜力;

通过持续研发和风险管理,AI在医疗、金融、大语言模型等更多方面实现了突破,开创了新的竞争领域,满足了用户在新的性能特征方面的新需求。

The S-curve represents a fundamental pattern: the curve accelerates due to positive feedback loops and then decelerates due to constraints.

When a constraint is broken, the positive feedback loop accelerates again until it encounters another constraint.

The curve of technological innovation can explain the following fact:

- Trough: When the S-curve of existing technology matures or approaches saturation, disruptive innovation begins to emerge.

This innovation often focuses on specific performance characteristics that are not the current mainstream demands but can meet the unique needs of certain user groups.

However, the overall initial performance of the new technology is relatively low, even inferior to the existing technology, which makes the decision of leading companies in the existing technology to invest in disruptive innovation early seem less reasonable. - Rapid Growth: As R&D investment increases, the technology accelerates its development, and performance significantly improves, eventually surpassing the existing technology.

With technological progress and changes in user preferences, the performance characteristics that were not mainstream before become the new focus of the market.

The unique advantages of the new technology start to meet or exceed the new demands of users, driving it from the niche market to the mainstream.

There is another type of innovation progress:

reducing performance in a specific dimension but improving it in other dimensions (for example, reducing flexibility but making it easier to deploy and use), which also counts as a "disruption" to the original innovation. - Maturity: The development of the technology tends to level off, with limited room for performance improvement and diminishing marginal benefits of further improvements. The curve approaches its peak.

- It is important to note that the process from the trough to surpassing in disruptive innovation requires effective risk management. Early performance compromises mean that the new technology may face challenges such as low market acceptance or long investment return periods, and successful disruption depends on the optimization of R&D strategies and the timing of market entry.

For instance, in its early development, artificial intelligence was less stable than traditional algorithms, but it demonstrated potential in pattern recognition and data processing.

Through continuous research and development and risk management, AI has achieved breakthroughs in more areas such as healthcare, finance, and large language models, opening up new competitive fields and meeting users' new demands in terms of new performance features.

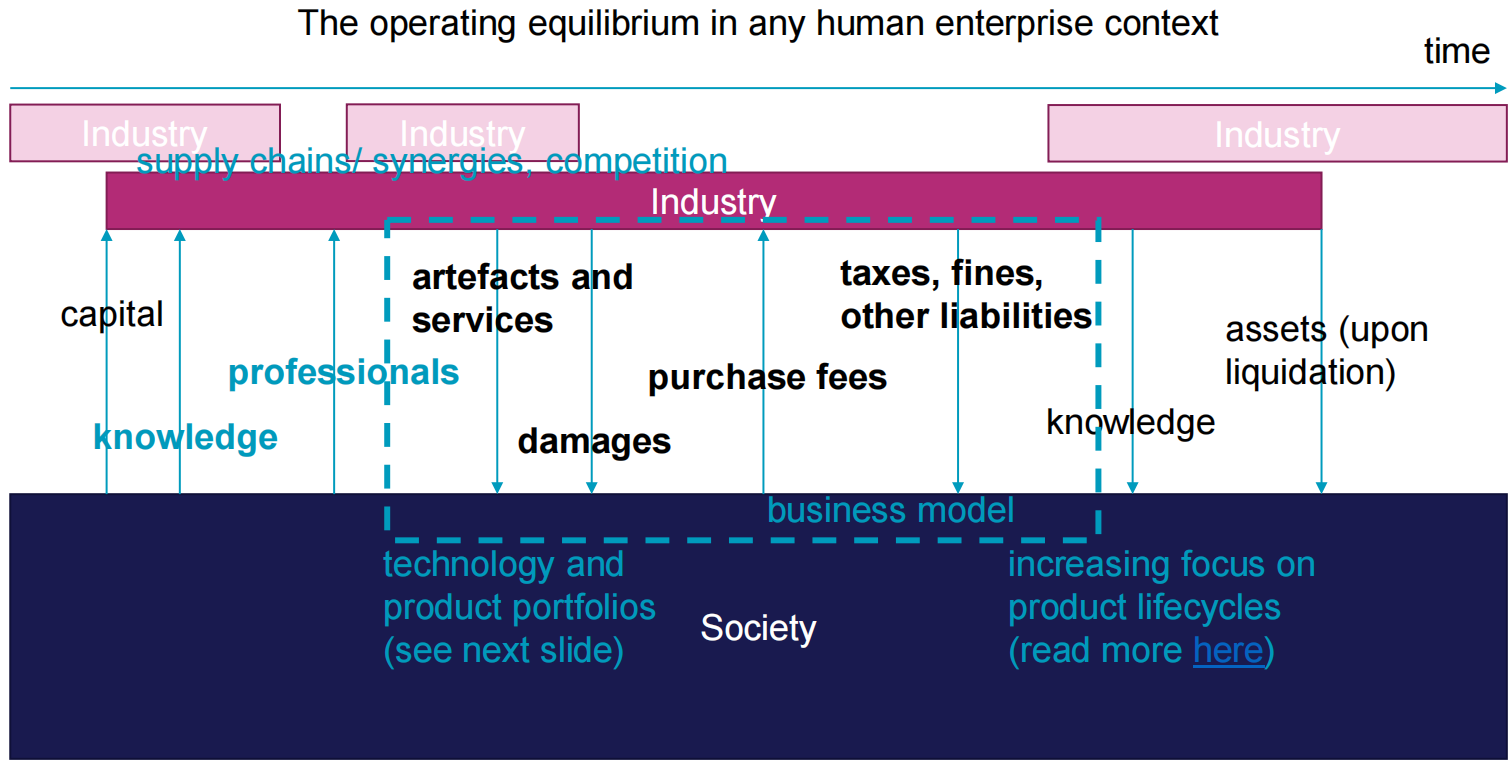

技术企业和社会的关系

随着时间的推移,技术企业和社会的互动如下:

- 社会为企业提供资本、知识和专业人才,支持技术研发,形成产品和服务,社会向企业支付费用以购买产品;

此外,关于本企业和其他企业的互动,技术企业依赖供应链获取资源(如原材料、技术组件),通过与供应商或合作伙伴的协同效应提升效率。同时,需应对行业内的竞争(如价格、技术或市场份额竞争)。 - 企业可能对社会带来损害(例如销售的飞机因为设计缺陷坠机,或不当的产品制造引发信任危机),此外也通过交税、缴纳罚款和其他债务,承担社会责任;

- 企业积累的知识可以回馈社会;

- 企业在生命周期的末端面临破产清算,其资产被处置并流回社会。

这里需要注意的是,图中的“商业模型”(另有说法是“技术与产品的组合”)主要包括:企业给社会交付产品和服务、带来损害、税务与罚款等社会责任;社会给企业钱来购买产品。

另一个现象是,关于商业模型,当今社会日益重视产品生命周期,包括可持续性、使用寿命和废弃处理等。

结论:技术企业通过技术研发和产品组合管理,将资本和人才转化为产品和服务,贯穿整个生命周期,是产业与社会的桥梁。

Over time, the interaction between technology enterprises and society has been as follows:

- Society provides enterprises with capital, knowledge and professional talents, supports technological research and development, and forms products and services. Society pays enterprises for the products purchased.

In addition, regarding the interaction between this enterprise and other enterprises, technology enterprises rely on the supply chain to obtain resources (such as raw materials and technical components), and enhance efficiency through the synergy with suppliers or partners.

At the same time, they need to deal with competition within the industry (such as price, technology or market share competition). - Enterprises may cause damage to society (for example, an aircraft sold by the enterprise crashes due to design defects, or improper product manufacturing leads to a trust crisis), and also assume social responsibilities by paying taxes, fines and other debts.

- The knowledge accumulated by enterprises can be returned to society.

- At the end of their life cycle, enterprises face bankruptcy liquidation, and their assets are disposed of and flow back to society.

It should be noted here that the "business model" (also referred to as the "combination of technology and products") in the figure mainly includes: enterprises delivering products and services to society, causing damage, paying taxes and fines, etc., as their social responsibilities; society providing money to enterprises to purchase products.

Another phenomenon is that in today's society, there is an increasing emphasis on the product life cycle in terms of business models, including sustainability, service life and waste disposal, etc.

Conclusion: Through technological research and development and product portfolio management, technology enterprises transform capital and talent into products and services throughout their entire life cycle, serving as a bridge between industry and society.

航空器任务需求和复杂度的增长

由于现代航空器需要更高的性能(如续航、油耗、速度),和更多高级功能(如舒适性),其设计和制造的复杂度显著上升。

此外,目前少数大型企业主导了航空航天行业,这导致竞争非常激烈,新技术逐渐标准化(“创新商品化”),厂商难以通过创新实现差异化竞争。

为应对市场压力,厂商需要降低成本、缩短开发时间、减少资源消耗,因此利用数字工具和仿真技术,设计和测试航空器的“虚拟化”技术得到应用。

Due to the fact that modern aircraft require higher performance (such as range, fuel consumption, and speed), as well as more advanced functions (such as comfort), the complexity of their design and manufacture has significantly increased.

Furthermore, at present, a few large enterprises dominate the aerospace industry, which leads to extremely fierce competition.

New technologies are gradually standardized ("innovation commercialization"), making it difficult for manufacturers to achieve differentiation through innovation.

To cope with market pressure, manufacturers need to cut costs, shorten development time and reduce resource consumption.

Therefore, the "virtualization" technology of designing and testing aircraft by using digital tools and simulation technology has been applied.

另一个转变是机载源代码数量的激增。我们可以观察到一个“指数”型增长的曲线,展示出航空器的软件复杂度随时间的快速增长。

这反映出设计文化从硬件开发转向软件开发主导,包括先进飞行控制、感知、导航、系统故障监控和容错控制等算法的应用,正日渐成为航空器功能和安全性的核心驱动力。

这里提出两点:

- 物理设计与软件开发的结合是现代航空工程的核心。

- 制造商需要在竞争中创新,同时通过成本控制和数字化手段保持盈利。

Another transformation is the explosive growth in the amount of on-board source code. We can observe an "exponential" growth curve, demonstrating the rapid increase in the software complexity of aircraft over time.

This reflects the shift in design culture from hardware development to software development as the dominant force, including the application of advanced flight control, perception, navigation, system fault monitoring and fault-tolerant control algorithms, which are increasingly becoming the core driving forces for the functionality and safety of aircraft.

Here are two points proposed:

- The integration of physical design and software development is at the core of modern aerospace engineering.

- Manufacturers need to innovate in the competition while maintaining profitability through cost control and digital means.

产品开发的时间线

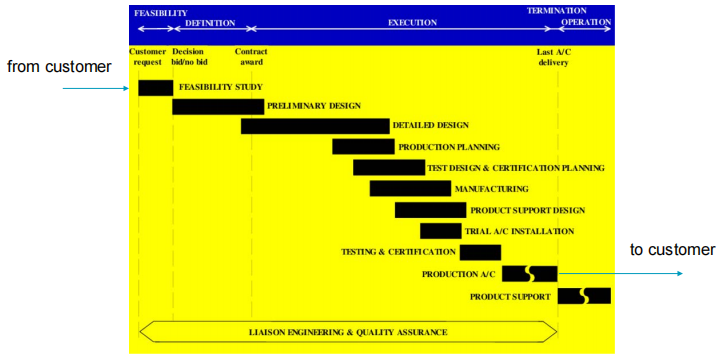

首先,按时间顺序,简要介绍一下各个步骤:

-

可行性:客户提交需求,公司评估项目可行性,通过后客户决定是否提交报价。

-

定义:客户出价后,公司进行初步设计,构建基本结构和功能。

若客户接受该初步设计,则双方签订合同。

初步设计将稍微延伸到签订合同后的执行阶段。 -

执行阶段:

- 详细设计:从签订合同前开始,是完善产品并完成最终设计的步骤。

- 生产规划:对制造过程中资源、时间、物流等的规划。

- 测试设计和认证规划:设计对产品的测试方案,并计划好产品的认证流程。

- 制造。

- 产品支持设计:对产品交付后的支持系统和服务进行设计,如培训、维修保障。

- 试验飞机安装:把产品安装在试验飞机上。

- 测试和认证:按照之前设计的方案,验证产品性能,并获取必要的认证。

- 全面生成飞机。最后一架订单飞机交付给客户,标志执行阶段的结束。

-

运作阶段:为客户持续提供产品支持和保障。

-

联络工程与质量保证:这一活动贯穿主要阶段,从可行性研究开始至产品支持结束,确保质量标准并解决工程问题。

First, in chronological order, briefly introduce each step:

-

Feasibility: The client submits the requirements, and the company assesses the project's feasibility. If approved, the client decides whether to submit a quotation.

-

Definition: After the client makes an offer, the company conducts a preliminary design, building the basic structure and functions. If the client accepts the preliminary design, both parties sign a contract. The preliminary design will slightly extend into the execution phase after the contract is signed.

-

Execution Phase:

- Detailed Design: Starting from before the contract is signed, it is the step to refine the product and complete the final design.

- Production Planning: Planning of resources, time, logistics, etc. during the manufacturing process.

- Test Design and Certification Planning: Designing the test plan for the product and planning the certification process for the product.

- Manufacturing.

- Product Support Design: Designing the support systems and services for the product after delivery, such as training and maintenance support.

- Installation on Test Aircraft: Installing the product on the test aircraft.

- Testing and Certification: Verifying the product performance according to the previously designed plan and obtaining the necessary certifications.

- Full-scale Production of Aircraft. The delivery of the last ordered aircraft to the customer marks the end of the execution phase.

-

Operation Phase: Continuously providing product support and assurance to the customer.

-

Liaison between Engineering and Quality Assurance:

This activity runs through the main phases, from feasibility studies to the end of product support, ensuring quality standards and solving engineering problems.

我们可以总结出如下知识点:

- 客户参与(Customer Involvement) :流程以客户请求为起点,以交付客户为终点,强调以客户为中心的设计和开发。

- 迭代设计过程(Iterative Design Process) :通过初步设计和详细设计两个阶段,逐步完善产品,体现设计的迭代性。

- 并行活动(Parallel Activities) :如联络工程与质量保证与主要阶段并行进行,显示持续的质量控制和工程支持的重要性。

- 测试与认证(Testing and Certification) :在全面生产和交付前,测试和认证是确保产品符合安全和性能标准的关键步骤。

- 交付后支持(Support After Delivery) :产品支持在最后交付后仍持续,表明对客户满意度和产品可靠性的承诺。

We can summarize the following key points:

- Customer Involvement: The process starts with customer requests and ends with product delivery, emphasizing customer-centered design and development.

- Iterative Design Process: Through two stages of preliminary design and detailed design, the product is gradually refined, demonstrating the iterative nature of design.

- Parallel Activities: Activities such as liaison engineering and quality assurance are carried out in parallel with the main stages, highlighting the importance of continuous quality control and engineering support.

- Testing and Certification: Before full-scale production and delivery, testing and certification are crucial steps to ensure that the product meets safety and performance standards.

- Support After Delivery: Product support continues after final delivery, indicating a commitment to customer satisfaction and product reliability.

Being a professional

这一部分先不写得了。

浙公网安备 33010602011771号

浙公网安备 33010602011771号